Economic, Life Cycle, and Market Analysis

NREL's economic, life cycle, and market analysis researchers provide comprehensive analyses that inform pathways for accelerating the successful commercialization of bioenergy and bioeconomy technologies.

Advancing bio-based fuels, materials, and products from proof-of-concept to market can be a lengthy and arduous journey. To quantify the materials and energy demands of bioenergy processes and technology pathways, NREL researchers use their rigorous Materials Flow through Industry (MFI) modeling tool.

NREL also focuses on techno-economic analysis (TEA) and life-cycle analysis (LCA) to quantify economic viability and environmental impacts, respectively. Together, the MFI tool and powerful process modeling highlight technical and cost drivers of bioenergy advances.

Flagship Projects

Researchers are developing new technologies and processes to convert waste carbon dioxide (CO2) from U.S. biorefineries and industrial sites into low-cost e-fuels. NREL collaborates with the U.S. Department of Energy's CO2 Reduction and Upgrading for e-Fuels Consortium to perform TEA and LCA of emissions utilization technologies. Data developed from this project have been used to improve costs and efficiencies.

Specific outcomes include:

- TEA results with key cost drivers for these utilization technologies

- LCA results with an expanded, updated GREET® CO2 utilization LCA module for relevant technologies covering electricity generation, hydrogen production, and CO2 sourcing.

The utilization projects include feasibility studies that support the consortium and other key agencies in efforts to produce reliable, abundant energy. Outputs from this project include valorization of CO2 in new technologies and identification of bottlenecks/hot spots of costs in these advancements. The ultimate result will help increase efficiencies and global competitiveness.

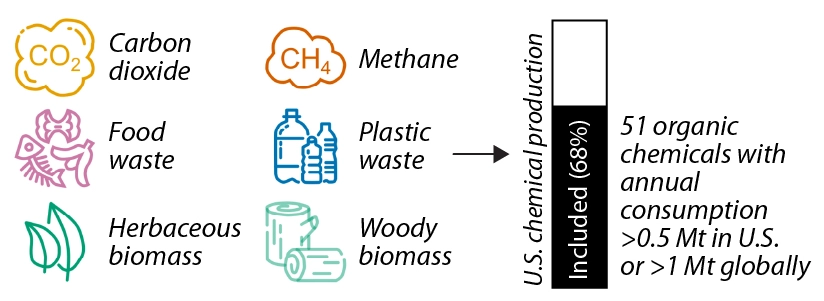

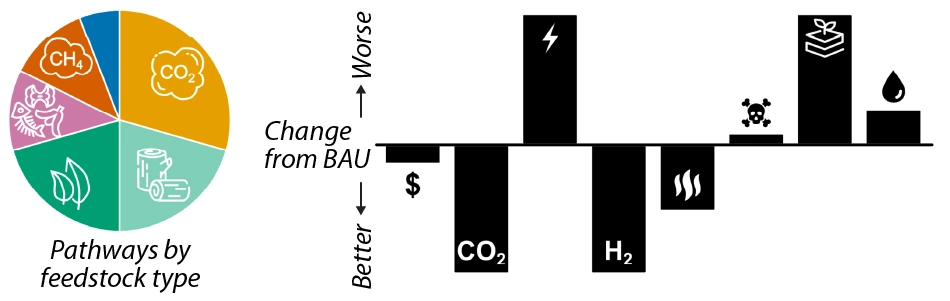

Current research and development lack a quantitative roadmap for prioritizing alternative chemical production. NREL researchers have evaluated the economic and environmental impacts of using domestic biomass and waste to produce 51 high-volume chemicals, aimed at boosting U.S. chemical sector competitiveness. Each of these 51 chemicals are consumed annually in quantities greater than 1 million metric tons (Mt) globally or 0.5 Mt in the United States. More than 200 alternative production pathways were identified, and 88 were analyzed using TEA, LCA, and multi-criteria decision analysis. A linear optimization model further assessed pathway combinations for cost reduction to support biomanufacturing.

Goal:

Identify alternative production pathways for high-impact petrochemicals based on resource use, costs, and environmental impacts.

Outcomes:

Economically and environmentally feasible alternative pathways using domestic feedstocks exist for 48 of 51 chemicals, half with a high technology readiness level. Possible implementation by 2050:

R&D Opportunities

Significance and Impacts

The outputs from robust TEA and LCA models may be used to estimate production cost intensities that guide research priorities and optimize economic potential for innovations in transportation (including marine and bio-derived aviation fuel) and industry (including petrochemical and chemical precursors).

Contact

Share

Last Updated Sept. 3, 2025