Recovery, Reuse, and Redesign of Waste Plastics

NREL valorizes waste plastics (including textiles, composites, and rubbers) through innovative and scalable recycling processes, developing mechanical, biocatalytic, and chemical recycling technologies to impact the largest variety of potential feedstocks.

Plastics are vital to America's economy and daily life, driving innovation, convenience, and job creation. New technologies and processes can help manage plastic waste efficiently and cost-effectively while strengthening U.S. manufacturing competitiveness, creating business opportunities, and reducing waste.

Flagship Projects

The BOTTLE™ consortium focuses on the development of scalable and energy-efficient technologies to recycle, upcycle, and design next-generation plastics. To achieve this, BOTTLE™ emphasizes an analysis-first approach to guide research toward technologies with maximum impact across central economic and environmental metrics.

Supported by the U.S. Department of Energy's (DOE's) Bioenergy Technologies Office and Advanced Materials and Manufacturing Technologies Office, BOTTLE is led by experts from multiple partner national laboratories and universities with demonstrated experience in process development and integration, chemical catalysis, biocatalysis, material science, separations, modeling, economic analysis, and sustainability assessment. Learn about BOTTLE's DOE-funded collaborations.

Contact: Katrina Knauer

Polymers are now produced globally at nearly 1 trillion pounds per year. NREL creates new materials from bio-based and/or waste plastics feedstocks, including materials designed for easier recycling at the end of use.

NREL's polymer science and engineering researchers:

- Have the capability to analyze every polymer ever produced, including emergent polymers. This enables a fundamental understanding of technologies related to plastics, including new recycling technologies and the development of new materials.

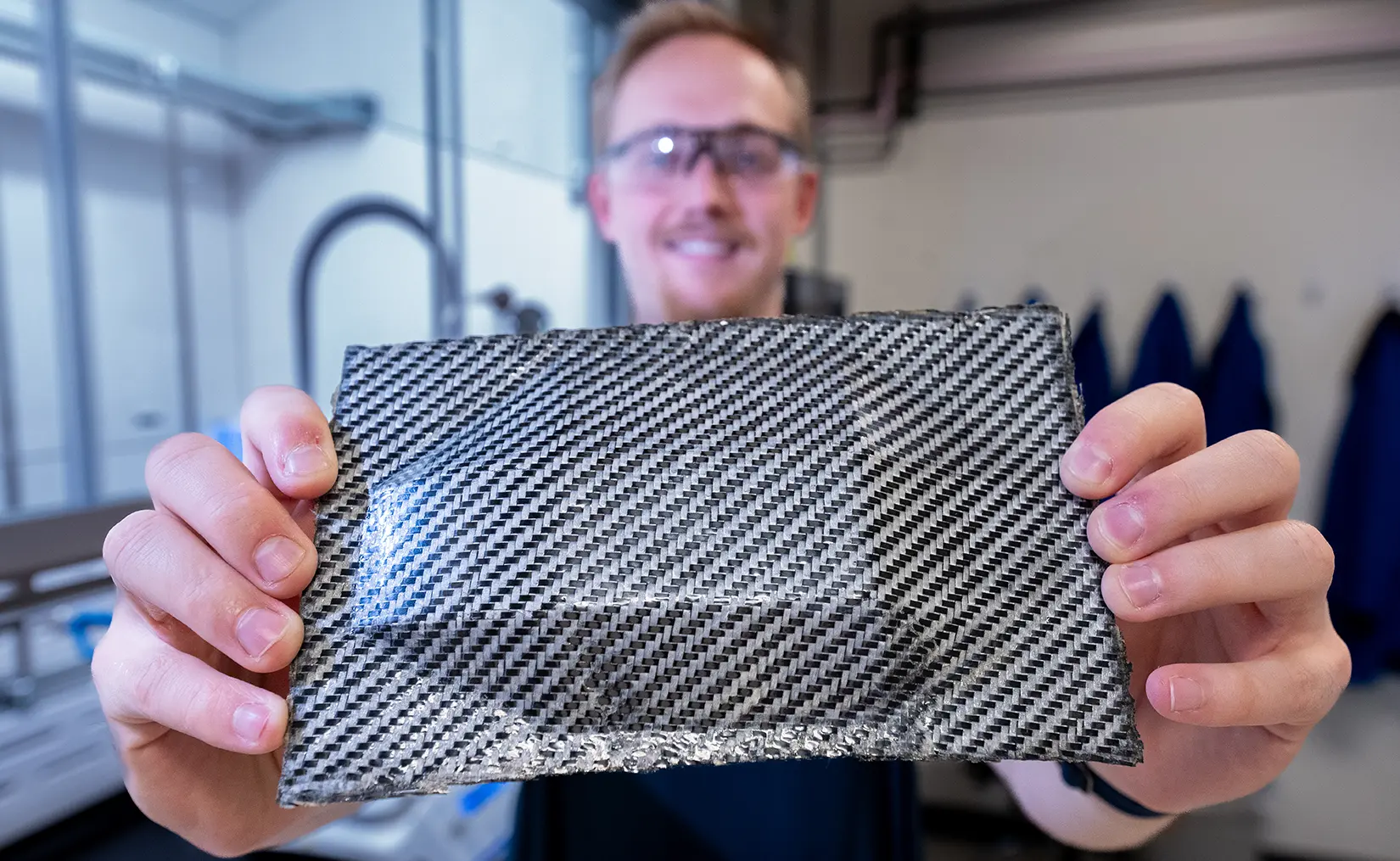

- Develop new chemistries to facilitate the recyclability of many emergent materials, including composites. By enabling the recyclability of composites, we can lower material costs for carbon fiber and composites broadly while fortifying the materials

supply chain.

- Produce innovative recycling technologies to handle today's plastics waste streams. These technologies seek to expand the plastics and polymers material supply chain by enabling applications beyond a material's first life.

- Develop new polymer and material formulations from waste feedstocks, such as lignin-derived compounds from biomass, that have better performance in materials manufacturing or performance-advantaged characteristics.

Contact: Nicholas Rorrer

Significance and Impacts

Upcycling plastics and designing new polymers are key drivers in a robust and cost-efficient bioeconomy. Harnessing the power to recover, reuse, and redesign these ample waste streams represents an opportunity to build secure, resilient domestic energy supply chains.

Contact

Share

Last Updated Sept. 4, 2025